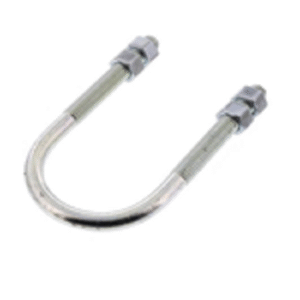

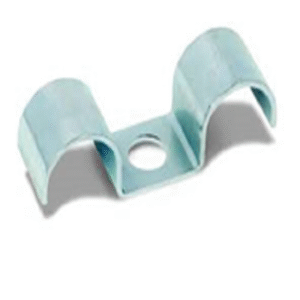

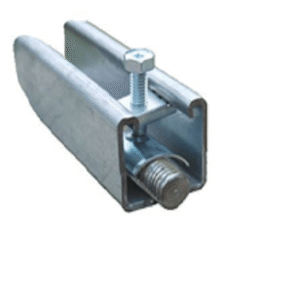

OASIS offers a very wide range of pipe fixing solutions for MEP projects widely used in applications like; central air condition, fire fighting, plumbing and electrical networks.

This range includes but not limited to:

Common Features

Material

Carbon steel alloy according to ASTM A283C and DIN 17100 standards – Steel grades 37 & 34.

Finish

Electro-galvanized plating with thickness ≥ 8 micron according to ASTM A90 – A90M standard.

Manufacturing

According to ANSI/MSS SP 58 & MSS SP 69 standards.

Options Upon Request

Material or Finish

For corrosion resistant applications.

- Stainless-Steel 304 alloy or Magnisum 201 alloy for body.

- Artelon for rollers.

- Hot-dip galvanization at outsource service provider.

Customization

- Special thickness and width of materials flexibility.

Isolation

- Neoprene rubber EPDM profile lining with 2 mm thickness; for noise and vibration damping, tested according to ASTM D412 and DIN 53504 standards.

Over-sizes

- with saddles and/or thermal insulation such as Armaflex and Rockwool.